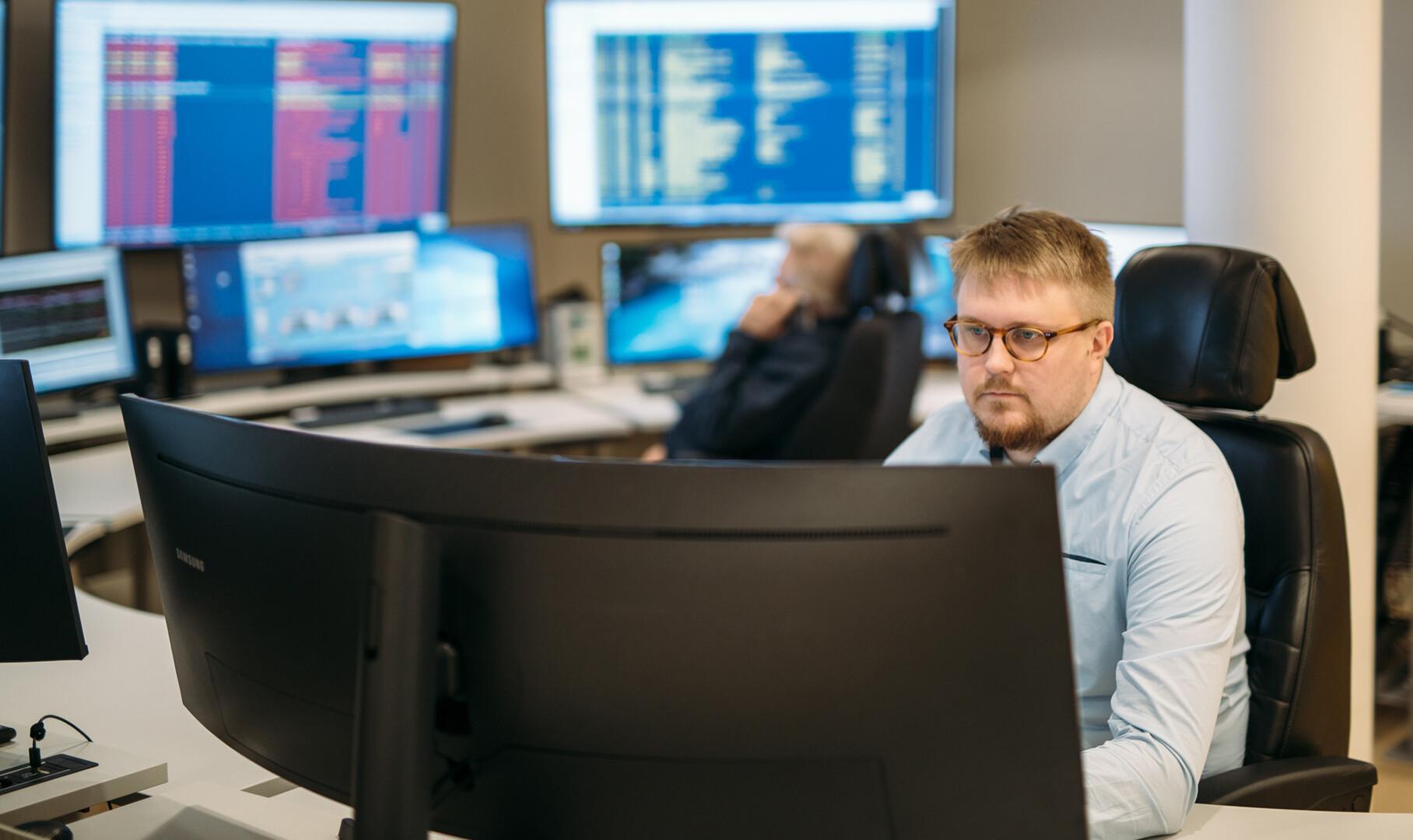

Operational center overseeing the energy plant

Adven’s operational center in Vantaa, Finland monitors and develops operations of more than a hundred energy plants round the clock. The aim is to avoid disturbances with proactive monitoring. A significant role is also played in the optimization of the operations of energy plants. Most of the alarms can be dealt with remotely. For the customers, this means safe and reliable energy production.

The impressive row of PC screens in Adven’s operational center in Vantaa is under the watchful eye 24/7. Screens show a huge amount of real-time data of the operations of more than one hundred energy plants. In the middle, there are two alarm displays which show possible disturbances in the plants.

Sites monitored from Vantaa include heating, evaporating, refrigeration and geoenergy plants around Finland: from Hanko to Kittilä and from Vaasa to Joensuu. In addition, the operational center in Vantaa monitors three industrial energy sites in Sweden. Other facilities in Sweden are monitored locally. The site operations in Estonia are controlled from a similar operational center in Tallinn.

Alarms from the facilities are immediately responded to.

“First, we assess whether the situation could be resolved remotely. If it is possible, we start fixing the problem”, says Adven’s Control Room Manager Miika Korhonen.

From the operational center, it is possible, for example, to start up secondary boilers, adjust fuel ratios and set off various device alarms. Approximately 80% of all the alarms can be resolved remotely.

We always play it safe

If the situation cannot be resolved remotely, center alerts the plant operator to the site to check the situation. Someone will always be on site within the agreed response times, regardless of the time of day.

Physical visits to the plant can be required, for example, if there are wider problems related to the fuel supply or components are broken. Issues related to the safety of the personnel, or the environment are also always checked on site.

“For example, if the surface of the oil trap well triggers an alarm, we will send our employee to check if there are oil leaks. In these cases, there is no room for speculation”, says Miika Korhonen.

All alarms do not require immediate actions, as some of them simply indicate that an alarm limit set for the process is approaching. Then, the operators will monitor the plant more closely and observe whether the process returns to normal or whether actions are needed. One of the purposes of the control system is to prevent technical problems and ensure that energy production is running smoothly.

Optimization increases efficiency

The operational center does not only solve problems, but it also has a significant role in the plant optimization. The aim is to achieve the best possible energy efficiency and usability of the plants.

The center constantly monitors the process data of all plants in terms of fuel consumption and energy production.

“Our goal is to strongly develop our processes so that we can better optimize and develop the operations of the plants from the control room. We compare different plants and introduce the best practices of one plant into other plants”, says Miika Korhonen.

Adven offers its customers energy as a service. Adven designs and implements the solution as its own investment and is, after this, responsible for the plant’s operations and maintenance. The customer receives the needed energy reliably and cost-efficiently.

“Our energy production plants are highly automated. There is rarely a need to intervene in the so-called basic running of the plant. In this way, we can operate a great number of plants centrally and focus more on developing and optimizing the operations”, says Miika Korhonen.

Strong experience in remote operations

Adven has decades of experience in the remote operating and monitoring of energy plants. The operational center has been in operation since 1983, and some of the employees have been working there since the beginning. Problem-solving skills and extensive expertise in the energy technology field is required from the center’s employees. Years of experience has helped to create excellent operating models.

“We are monitoring plants of several different types. We use our expertise as a team to take care of different fault and operation situations”, says Miika Korhonen.

Together with skilled plant operators, the control room provides its customers with the most undisturbed and cost-efficient energy production possible. With this group, everything is under control!

Read more:

Fully automated boiler house: Largest boiler house is being built for the Estonian food industry | Adven

Our partnership model and services for our clients: Energy as a Service® for industries and large properties | Adven

Why choose Adven?: Partner in the energy transition | Adven